Brunel Engraving Company has always been leading the pack for the latest technologies in the engraving industry. Our craftsmen are trained to the highest standards in the UK and understand the intricacies of each application, ensuring the perfect result for you. Here’s a look at some of the most common engraving techniques and when and where they would be appropriate.

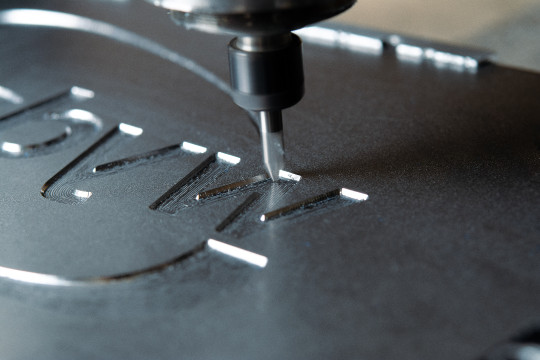

Rotary Engraving

Rotary engraving systems use a computer-controlled rotating cutting tool in a motorised spindle to remove surface material. The rotating cutting tool, or cutter, cuts into the surface of the material to a predetermined depth and produces a groove of the same shape and size as the tool.

A common application of rotary engraving is to remove or mill away the background to leave raised letters or images for a "cast" look or create braille print.

Laser Engraving

Laser engraving is ideal for both engraving and for cutting holes or shapes. CNC laser engraving allows for much finer marking and cutting than CNC milling. Depending on the type of laser used, a laser will either vaporise the material at which it is pointed, or it will change the material surface creating a contrast.

Lasers can engrave metals, wood, rubber, glass and plastics (including Perspex) as well as natural materials such as slate, marble and granite.

Chemical Etching

Originally, etching was the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio in the metal. As an intaglio method of printmaking, it is, along with engraving, the most important technique for old master prints, and remains widely used today. Today other chemicals are also used to mark surfaces or cut through other types of material.

The modern chemical etching process is a fast and cost-effective alternative to traditional engraving where very fine detail, large quantities of text and multiples of the same image are required.

Sublimination

Sublimation is a process whereby an inkjet printed image on special paper is transferred to a polyester-coated material when heat (200°C) and pressure are applied. The inks transfer and bond to the coating on the material giving a smooth and durable finish. Other heat transfer methods only apply colour to the surface of the substrate resulting in a finish that can be easily scratched or damaged. For instance, a colour photograph can be sublimed to a metal plate. Sublimation produces stunning and vibrant colours.

Anodic Printing

In Anodic Printing, ink is precisely applied directly onto the open-pored aluminum surface before the aluminum is sealed in a high-temperature water bath. This sealing process effectively encapsulates the ink within the aluminum, resulting in high-quality and enduring printed items.

Our Anodic Printing process is facilitated by a flatbed digital printer, which grants Brunel Engraving the ability to produce full-colour and photographic prints. This approach provides a distinct advantage over traditional screen printing since it eliminates the need for separate screens for each color setup.

Digital Printing

Digital printing is a method of printing from a digital-based image to a variety of media. It is ideal for producing small-run orders as there is less set up cost than traditional screen printing. It allows for on-demand printing, quick turnaround time, and changes to the image such as variable data. Brunel Engraving use these modern methods of digital printing to produce nameplates, plaques, office signs, control panels and industrial labels that cannot be produced by traditional print processes.

Brunel Engraving is capable of using all of the above methods to produce the perfect result. To find out more from our team about which technology is the best for your project, contact our customer service team here.