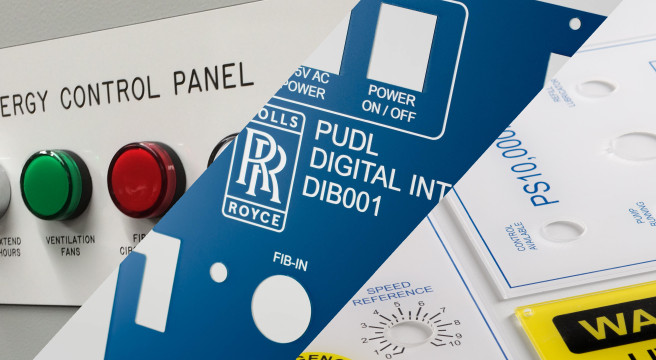

Control panels serve as critical components across various industries, facilitating the management and operation of complex systems. The material chosen for a control panel plays a significant role in performance, durability, and suitability for different environments. In this guide, we'll explore various materials commonly used for control panels, their characteristics, and applications to help you determine the best material for your specific requirements.

Traffolyte:

Traffolyte, a phenolic engraving laminate, stands as a stalwart choice for interior control panel applications. Renowned for its electrical insulation properties, traffolyte excels in industrial environments where clear labelling and signage are imperative. Its versatile nature makes it ideal for control panel labels, offering durability and reliability within internal conditions.

Low Cost Favourite: renowned budget friendly choice throughout the UK industrial market.

Chemical & Electrical Resistance: Exhibits high resistance to acid & alkali. Traffolyte also has excellent electrical insulation properties, making it ideal for industrial use, particularly for electrical control and panel labels.

Engraving Capability: CNC engraved which offers versatility in hole cutting and engraving, although this engraving process has limitations with very small details.

Rigid Nature: Consists of three robust & sturdy, hard wearing layers. While rigid, Traffolyte can de-laminate over long periods of time in very harsh conditions and is prone to snapping when bent. For a more flexible, exterior grade alternative, we suggest Impact Acrylic.

Colour Options & Finish: Available in a range of standard colours with a glossy finish.

UV Stability: Not 100% UV stable, and prolonged exposure to exterior conditions can affect colour and structural integrity, leading to delamination over time.

Impact Acrylic:

In the realm of control panels, Impact Acrylic emerges as a versatile contender. With its resilience against impact and weather, Impact Acrylic proves itself a valuable asset for both interior and exterior control panel applications. Whether it's detailed engraving for identification or vibrant contrasting colours for visibility, Impact Acrylic offers a wide range of possibilities for control panel customisation.

Detailed Engraving: Utilises CO2 lasers for finer and more detailed engraving, critical for reproducing items like barcodes, QR codes, and small lettering.

Weather Resistance: Exhibits excellent weather resistance and UV stability, suitable for both indoor and outdoor applications without delamination.

Versatility: Easily fabricated and machined, enabling a wide range of hole shapes and bespoke designs.

Layer Structure: Typically has two layers, contributing to strength and flexibility.

Colour Options & Finish: Available in a vast range of colours and finishes including a non-glare finish and textured finish which is durable, and resistant to fingerprints.

Flexible Nature: Capable of being heated and folded, providing versatility in fabrication and installation.

Cast Acrylic:

Cast acrylic, known as Perspex in the UK, is fast becoming the most popular choice with our clients due to durability, aesthetic look and ease of maintenance. First impressions count, even on control panels! Here are its key features:

Excellent Light Transmission: Provides clear visibility of control panel elements, enhancing user experience.

Wide Range of Colour Options: Offers versatility in design, allowing for customisation to match branding or aesthetic preferences.

Exceptional Durability: Withstands harsh environmental conditions, ensuring long-term performance.

Gloss Finish: Adds a sleek and polished look to control panels.

Full-Colour Print Capability: Allows for vibrant and detailed designs to be printed onto the material.

Vinyl Backing: Provides additional protection and durability for printed designs.

Easy to maintain: The front face can be cleaned easily as the design is printed on the reverse.

Laser-Cut Holes: Enables precise placement of holes for enhanced functionality and aesthetics.

ADA:

ADA materials revolutionize control panel signage, ensuring compliance and inclusivity. Here are its standout characteristics:

Clear Non-Glare Matte Finish: Ensures visibility while reducing glare, enhancing readability of control panel signage.

Reverse Printing: Protects the printed design from wear and tear, ensuring longevity.

Protective Vinyl Backing: Adds durability and resistance to environmental factors, extending the lifespan of the signage.

Laser-Cut Holes: Facilitates accurate positioning of holes, enhancing both functionality and aesthetics.

Resistant to Fingerprints: Maintains a clean and professional appearance, even with frequent use.

UV Stable: Withstands exposure to sunlight without fading or degradation, suitable for outdoor applications.

Stainless Steel:

Stainless steel epitomises durability and resistance in the domain of control panels. With its exceptional corrosion resistance and robustness, stainless steel control panels thrive in harsh industrial environments. From marine settings to chemical facilities, stainless steel stands as the dependable choice, ensuring longevity and reliability in critical operations.

Durability: Highly durable, 316 Marine Grade, which offers exceptional resistance to corrosion. Ideal for use in industries where durability and resistance to corrosion are paramount, such as marine, chemical, and food processing industries.

Suitability: Suitable for both interior and exterior use, particularly in harsh environments exposed to corrosive elements or aggressive chemicals.

Engraving: Engraved to a depth to maintain integrity even in aggressive conditions. We also offer matte black laser engraving, this method is still durable, but also a cost effective engraving process.

Aesthetic: Available in various finishes including, dull polished, and bright polished, offering versatility in design.

Anodised Aluminium:

A versatile material, offering both engraving and printing capabilities for control panel applications. Its durability and resistance to corrosion make it suitable for a wide range of control panel components. Anodised aluminium lends itself to customisation, providing control panels with both functionality and aesthetics.

Engraving:

Anodised aluminium can be engraved using various methods, including rotary engraving or laser engraving. This process creates precise and detailed markings on the surface of the material, ideal for creating control panel components.

Engraving offers excellent durability, as the aluminium is marked directly into the surface of the aluminium, ensuring longevity even in harsh environments.

Printing:

Alternatively, anodised aluminium can be printed using advanced printing techniques such as anodic printing. This allows for full-colour printing, photographic prints, and intricate designs to be applied directly to the surface of the aluminium.

The printing process results in vibrant and high-resolution graphics, making it suitable for coloured branding, signage, and functional elements on control panels, such as yellow emergency stop markings.

Process:

Engraving Process: Engraving involves removing material from the surface of the aluminium using specialised rotary machines or lasers to create the desired design or text.

Printing Process: Printing is achieved by applying ink or dyes onto the surface of the anodised aluminium, which is then sealed to ensure durability and longevity.

Capabilities:

Durability: Anodised aluminium is highly durable and resistant to scratches, chemicals, and environmental factors, ensuring long-lasting performance in various applications.

Versatility: Whether engraved or printed, anodised aluminium offers versatility in customisation, allowing for the creation of unique and personalised control panel components.

By leveraging the engraving or printing capabilities of anodised aluminium, you can create customised control panels that meet your specific requirements for durability, aesthetics, and functionality.

Brunel have many materials suitable for the rigorous industrial environments found across the UK, each option offers unique advantages tailored to your specific requirements. Traffolyte excels in industrial environments with its electrical insulation properties, while Impact Acrylic proves its versatility in both interior and exterior applications. Stainless steel stands as the epitome of durability, ideal for harsh conditions, and Anodised Aluminium offers a choice of engraving and printing capabilities for customised control panel components. Cast Acrylic provides exceptional light transmission and durability, making it an ideal choice for various environments, while ADA materials stand out with their non-glare matte finish, ensuring optimal visibility in all lighting conditions. By understanding the strengths of each material, one can craft control panels that not only meet functional needs but also endure the rigours of industrial operations with resilience and reliability.

If you need further assistance or guidance in selecting the best method for your control panel components, please contact us for expert advice and support.