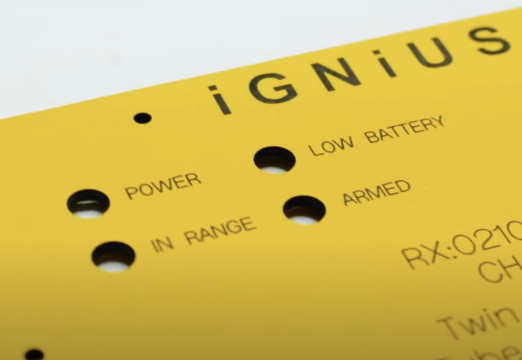

Rotary engraving is the process of using a rotating cutter in a motor powered spindle to cut into material in order to create engraved grooves which form raised characters or graphics. Rotary engraving can be used on a wide variety of material including acrylics, soft plastics, rigid plastics (phenolic), soft metals (brass and aluminium) and harder metals (steel and stainless steel).

How does Rotary Engraving work?

CNC rotary engraving systems use a computer controlled rotating cutting tool in a motorised spindle to remove surface material The rotating cutting tool, or cutter, cuts into the material surface to a predetermined depth in order to produce a groove of the same shape and size as the tool. The rate of the cutter rotation is known as the cutting speed and the lateral movement is the feed rate. Both the cutting speed and the feed rate have a profound effect on the quality of the finished cut. In general, softer material may have higher cutting speeds and feed rates and can be engraved in a single pass. Harder materials require lower cutting speeds and feed rates may need to be engraved in two passes. The first pass will remove most of the material and the second pass will create a clean cut.

Once cut, we often fill the engraved areas with a coloured paint to provide a contrast to the metal, we can use rotary engraving to leave raised letters or images for a “cast” look or to create Braille print.