Introducing Anodic Printing, a process of printing into the aluminium surface, providing a durable, scratch and solvent resistant finish. Used for products such as serial plates, labelling and VIN plates.

What is Anodic Printing?

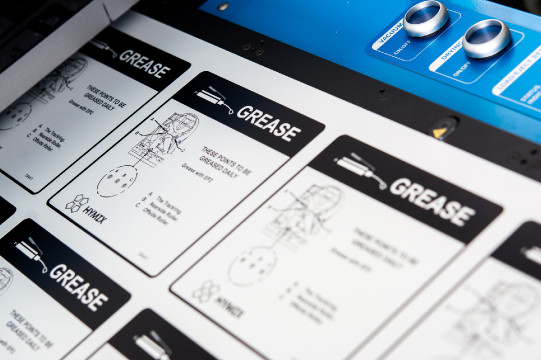

Anodic Printing (or otherwise known as Ano Printing or Ano marking) is a process of printing into the aluminium surface. providing a durable, scratch and solvent resistant finish. Used for products such as serial plates, labelling and VIN plates, this process is used on many types of machinery and vehicles, internal, external, and hardwearing environments.

We can also combine this process with our laser cutting service to offer high quality control panels cut to bespoke shapes.

How does Anodic Printing Work?

Ink is printed directly into a sheet of open pored aluminium before the aluminium is sealed in a hot water bath at high temperature. This process seals the pores of the aluminium encapsulating the ink and providing a high quality and durable printed item.

Anodic Printing Capabilities:

Our anodic process is completed via a flatbed digital printer, allowing Brunel Engraving to provide full colour and photographic prints, a clear advantage over a screen-printing process as we do not require a screen for each colour setup.

Material Stock is 1mm ,1.5mm & 2mm as standard, other thicknesses are available on request.